New standards of quality, safety and comfort of heating

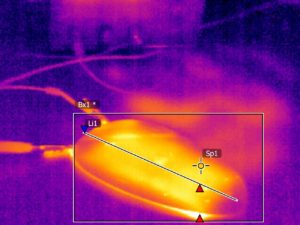

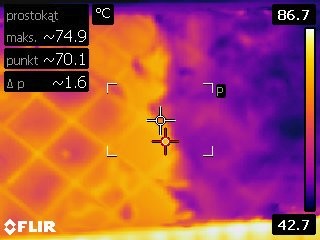

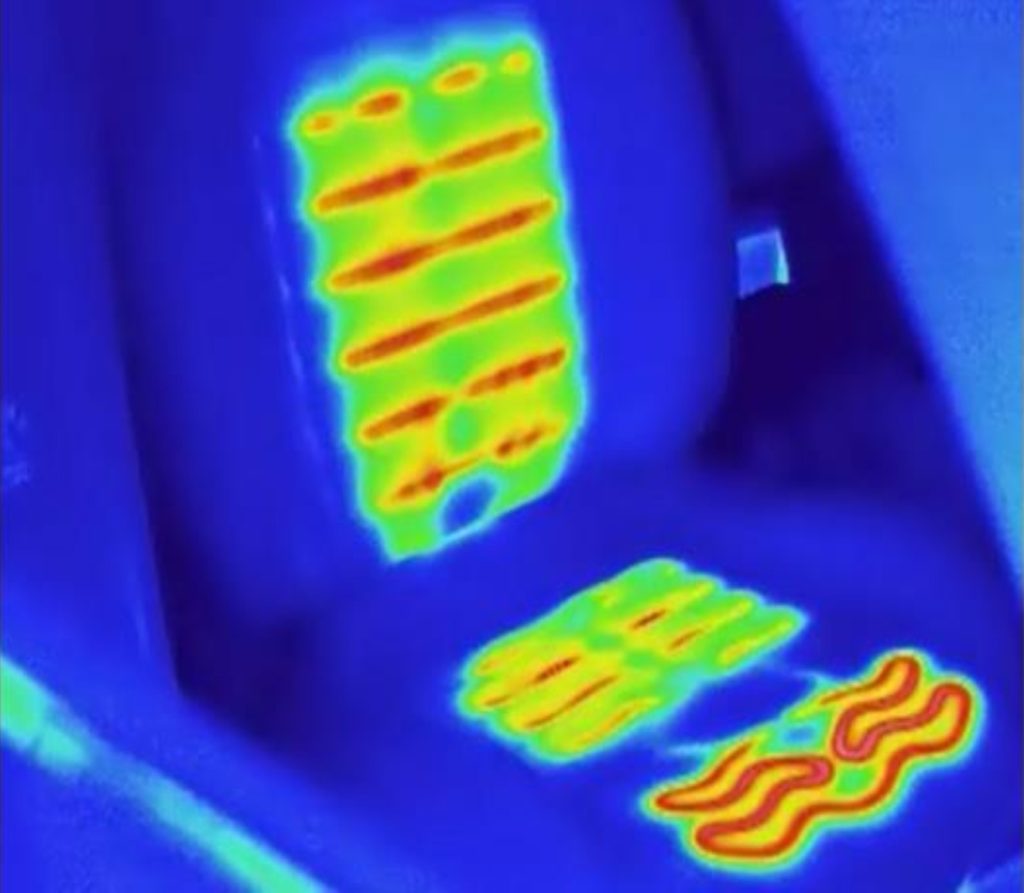

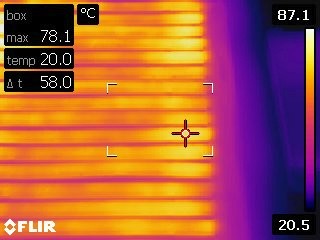

The technology that was developed in the ITP-System laboratories made possible to combine the electrical conductivity of carbon nanomaterials with excellent mechanical properties (elasticity, resistance to damage) of polymer elastomers. We replaced traditional solutions based on resistance wires using an advanced, homogeneous nanocomposite. The result of our work are mats and coatings with heating functions, which distinguishes even temperature distribution over the entire heated surface and fast response time in obtaining the desired temperature, as well as safe supply voltages (up to 24V for temperature 0 – 70˚C).

Principle of operation

ITP-System technology uses carbon nanomaterials that are deeply modified in our laboratories. Obtained nanocomposites are characterized by electrical conductivity, combined with high resistance to the for electricity during the operation of the device generates energy losses in for of the heat. Carbon nanomaterials are also excellent heat conductors, thanks to which, during the operation of the device, there is practically instantaneous emission of heat to the environment. The technology of our nanocomposite allows its application on many materials, such as: textiles, plastics, metal alloys, etc. Using various types of monomers and fillers it is possible to influence the critical features of the nanocomposite, such as flexibility, thermostability, tensile strength, mass rheology before the process cross-linking, giving self-extinguishing, biocidal and other properties. Precise control of the device temperature is possible thanks to simple control systems: voltage regulator, temperature sensor, thermostat and programmer.

Thanks to a small power supply voltage, it is possible to use a nanocomposite using energy from renewable sources and small batteries.

Usage

The main areas of application are: garment functionalization, construction, means of transport, medicine, emergency medical services, rehabilitation, household appliances, agriculture and special production (militaria, research and laboratory equipment, etc.).

New marketing advantages

The introduction of ITP-System heating technology does not adversely affect the previous functional characteristics of the products. However, it gives them heating properties, which opens up new areas of application. The durability of products equipped with functional heating elements made in the ITP-System technology is longer than with the use of classic heating systems using resistance wires. This is due to the fact that the heating mass does not contain any electrical circuits sensitive to burnout or tearing. As long as the entire plane remains continuous, it will be functional.

An innovative and specialized product with new properties allows its commercialization in a wide field of applications. Low voltage supply heating mats allow their safe and trouble-free use. Use in functional items to which children may have access does not pose a danger even if they are destroyed or flooded with water.

The use of heating mats made in the ITP-System technology allows you to economize the energy management thanks to the even temperature distribution on the entire heating surface. This limits the energy consumption that is needed to heat the spaces between the resistance wires in conventional devices.

More informations you can find in our catalogs and presentations!

|  |

|  |